<< Back

AUZIER APPLICATION SHEET

Auzier of Montpellier France has saved energy and time

Drying Gum Arabic at 70°C and Gelatine Product at 25°C

Using a DRYCOOL DHD8000 heat recovery system

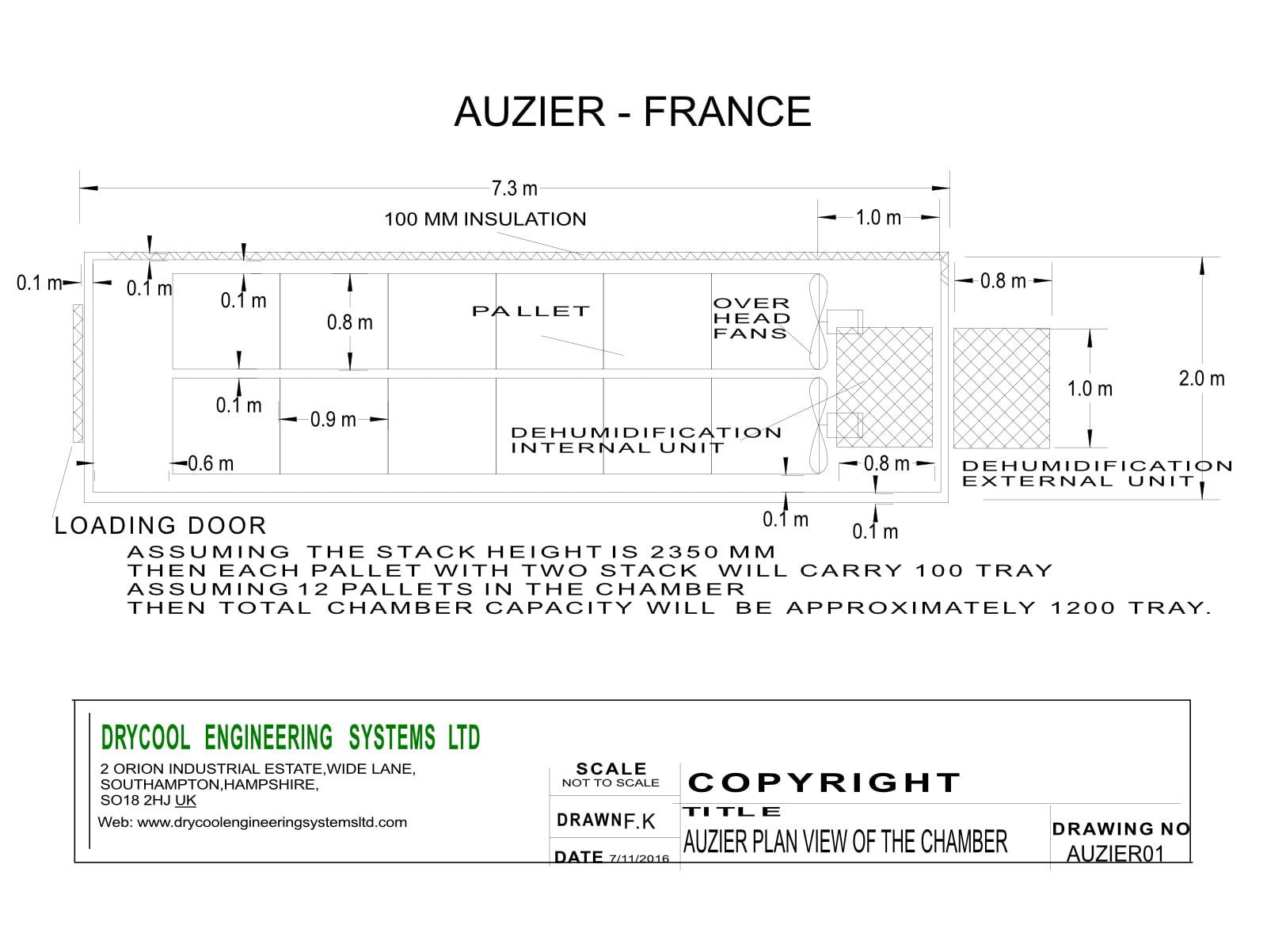

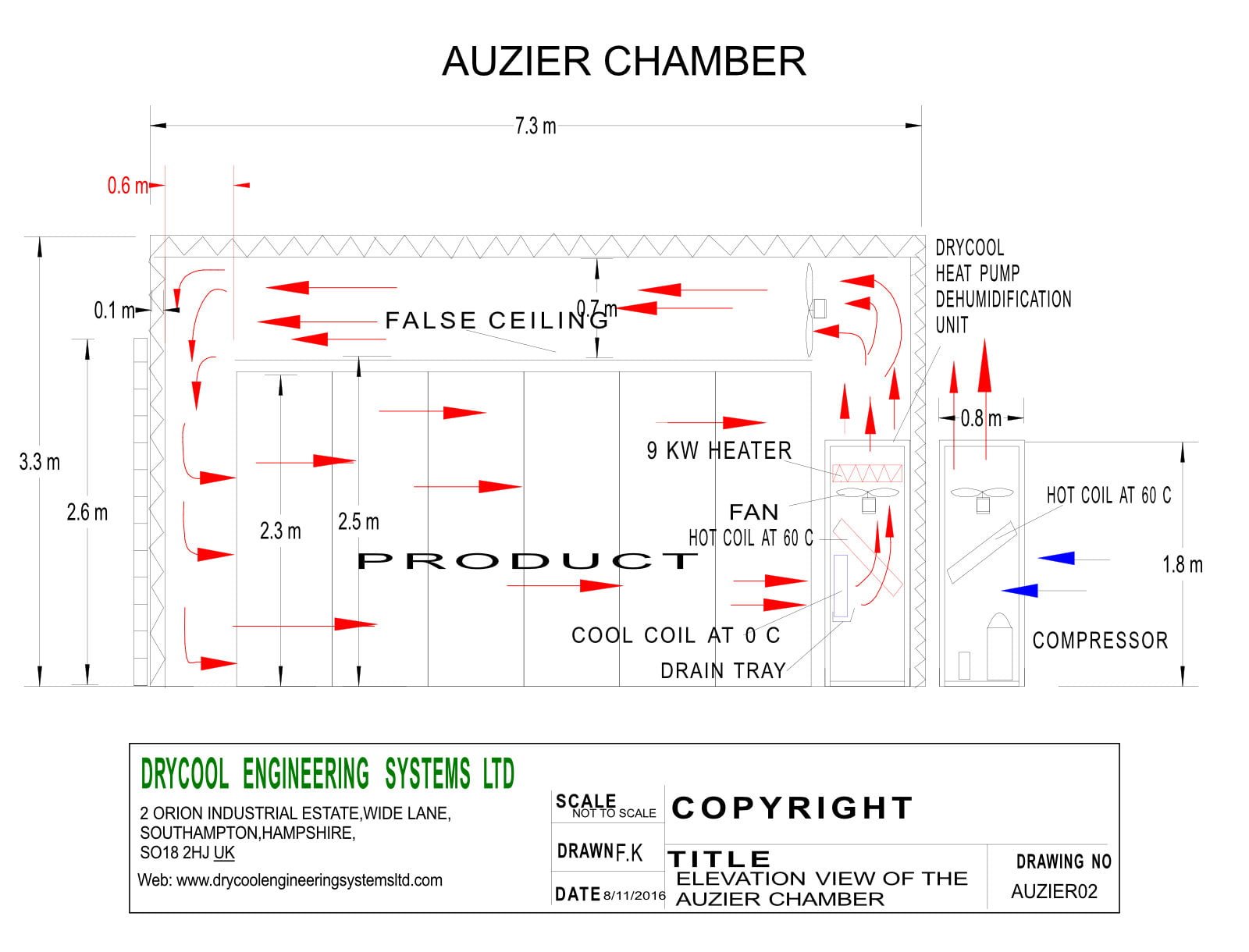

The Drying System

Internal Units

The internal unit houses the Cool Coil and the Hot Coil. The combination of the Hot Coil and the Cool Coil operates during the drying process of the Gum Arabic at 70° reducing the humidity to 10%. Resulting in the final moisture content of the starch of 6%.

Depositing the product into starch with a 6% moisture content enables a better-shaped product.

External Units

The external units of the system consist of the compressor and the auxiliary condenser unit for the second Hot Coil.

This houses the compressor and the auxiliary condenser or the second hot coil of the machine. The second condenser or the hot coil comes on during the 25°C operations for drying gelatine products this transfers the heat in the chamber to the atmosphere and therefore cools the product. There is no ventilation.

The traditional drying chambers use a vent system to dry the product in which case wet air comes in causing an increase in the moisture content of the starch and making the product surface wet.

The Drycool DHD 8000 system has no vent system therefore the product is not dependent on the weather because all the moisture extraction and cooling of the system is carried out using heat recovery and by refrigeration system.

The result is a perfect product at a low energy drying cost, consistent final moisture content and dependable quality.